24Hour Ready to Assist

24H Ready to Assist

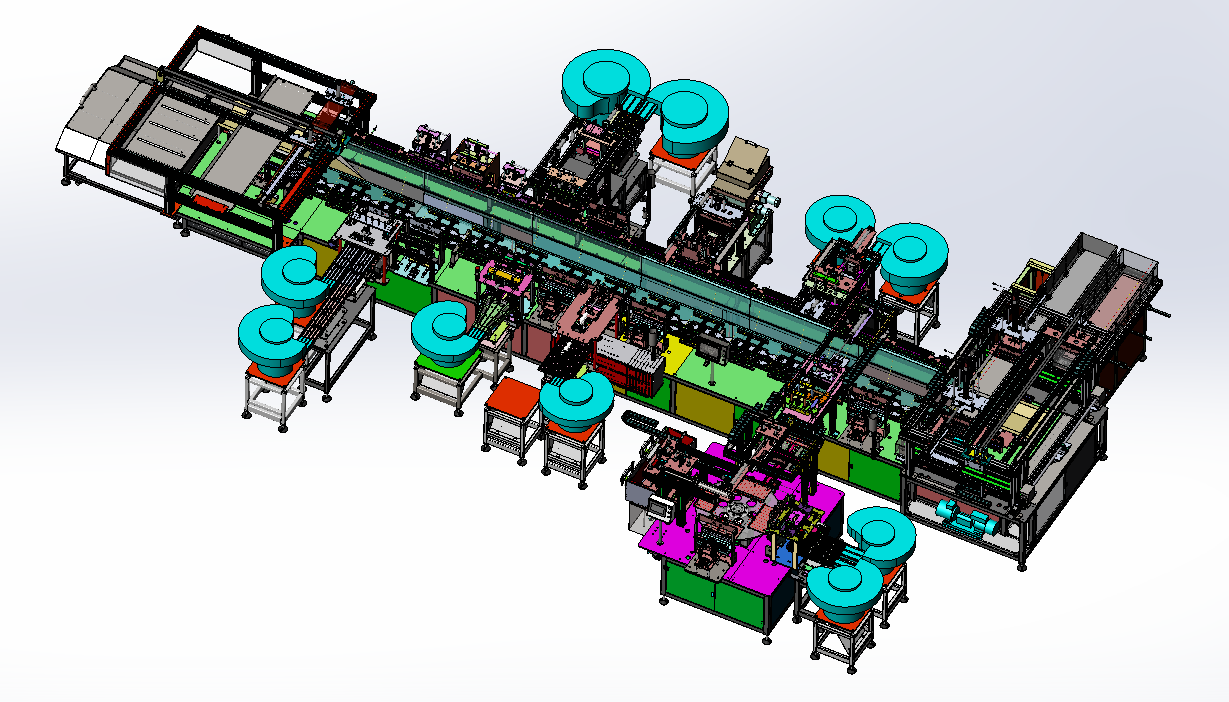

configuration

Pneumatic components: SMC

Photoelectric Sensors: Keyence/Panasonic

Touch Screen: WEINVIEW

PLC System: Mitsubishi

CCD Detection: Keyence/Cognex

Servo Moto: Taiwan Delta

Parameters

| Power | Voltage | Air pressure | Capacity | Pass rate |

|---|---|---|---|---|

| 5KW | 220V/380 V, 50 Hz | Clean compressed air 0.5 – 0.8 Mpa | 4500-5000pcs/h | ≥99% |

| Equipment size | Floor area | Operators required | One- time quantity of assembly |

|---|---|---|---|

| 11.7m*6.4m | about 75m² | 3 person | 10pcs |

Frequently Asked Questions

With so many years of experience in medical automation machines, we know that the following are questions that customers often ask, you can check the answers below. If you have any other questions, please feel free to contact us and we will respond to you quickly.

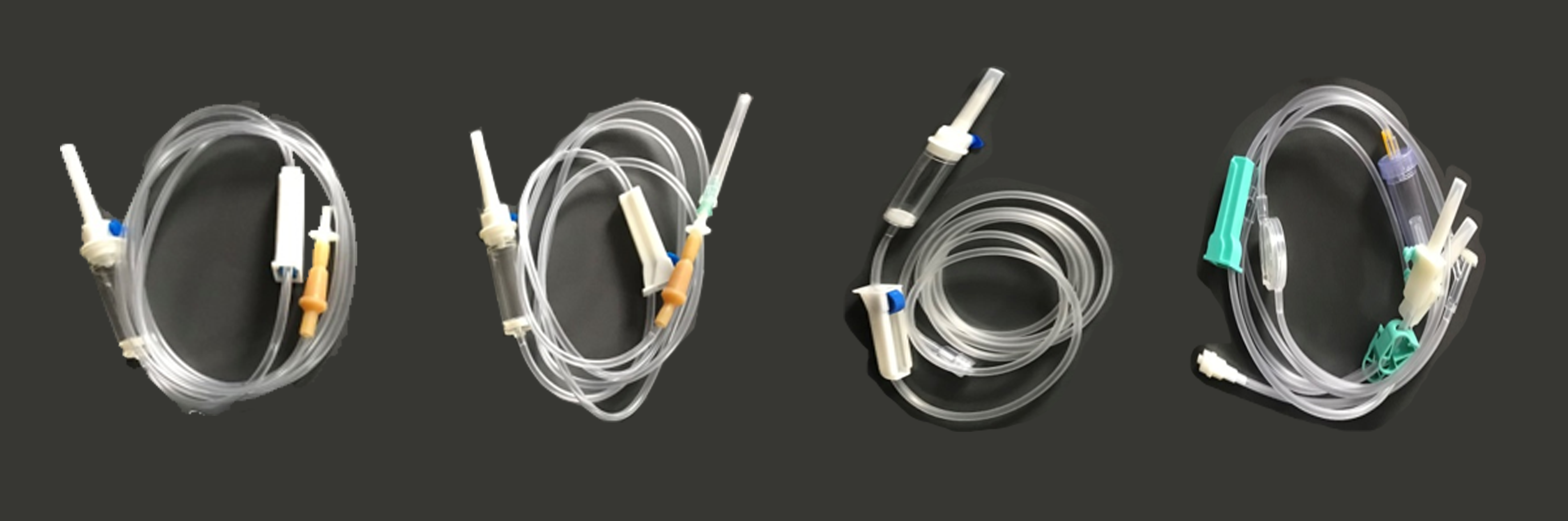

Normally, IV infusion set assembly machine is 5000pcs/hour with three workers.

IV infusion set assembly and packaging machine is 4500pcs/hour with seven workers.

Normally it will take approx. 120 days to complete production after receiving advance payment.

The function of our machine is to assemble all components together automatically. Our machines have the ability to improve output and production efficiency. Our machines are capable of removing defective components and products during operating automatically. It will not only improve product quality, precision and reliability, but also helps clients minimize labor costs and product costs.

1. If you’re able to produce all components in your factory or you can get all components from other suppliers, then you need 2 machines, drip chamber(6 parts) automatic assembly machine and IV infusion set automatic assembly machine.

2.If you are a new factory which plan to produce IV infusion set, we would like to introduce our cooperated partners and reputable suppliers to you, like injection machine factories, injection mold factories, PVC tube extruder machine factories, components factories, etc. We will assist you to find all related suppliers and components in our country. Please contact us for more details.

Yes, we are able to provide customized drawing for your exist workshop layout.

Yes, if you have a limited budget, we are able to design and produce semi-automatic assembly machines.

Yes, Our machines are equipped with the following testing processes, leakage testing, blockage testing, pullout testing, CCD visual inspection,etc.

Yes, it will automatically remove defective products, and stop the subsequent assembly process, effectively reduce the waste of raw materials and components.

Step 1.

Client :send products inquiry to supplier, including product details, photos, dimensions, workshop layout if available, and other requirements.

Supplier:send the quotation and make proposal for the project.

Step 2.

Client: After prices and details are confirmed, send the samples and components of the products to the supplier.

Supplier: Prepare the design drawing according to the samples and components for the machines, and send to client until the drawings have been confirmed by client. Then send sales contract and proforma invoice to client.

Step 3.

Client:Visit supplier’s factory if needed, and arrange the advance payment as stated in the sales contract.

Supplier:Start production and finish production within the agreed time, complete installation and debugging work in the factory before delivering, then inform the client.

Step 4.

Client: Arrange the balance payment as stated in the sales contract.

Supplier: Arrange the delivery to the loading port of destination port as stated in the sales contract.

Step 5.

Client: Inform the supplier when the machines arrived at the factory, inform the estimated date of installation required, and assist to apply visa for engineers and technicians from supplier if needed.

Supplier: Send the engineers and technicians to client’s factory to giving on-site installation and debugging assistance. Trial operation one week and ensure that the machines are in a normal operating condition.

Step 6.

Client: Confirm and sign on the acceptance report, arrange the balance payment as stated in the sales contract.

Supplier: Give technical guidance and personnel training at client’s factory, including drawing, process, operation, equipment maintenance, equipment performance and problem solving. Provide the after-sale service as stated in the sales contract.

We provide free repair,maintenance and technical support services within one year after equipment debugging qualified when clients in the normal use condition.

We stock quick-wear parts in our warehouse all year long, we will send quick-wear pars to you by express timely.

We will arrange on-site training for our customers, provide guidance on how to solve common faults.

When the machine cannot operate normally, we will provide online assistance immediately.