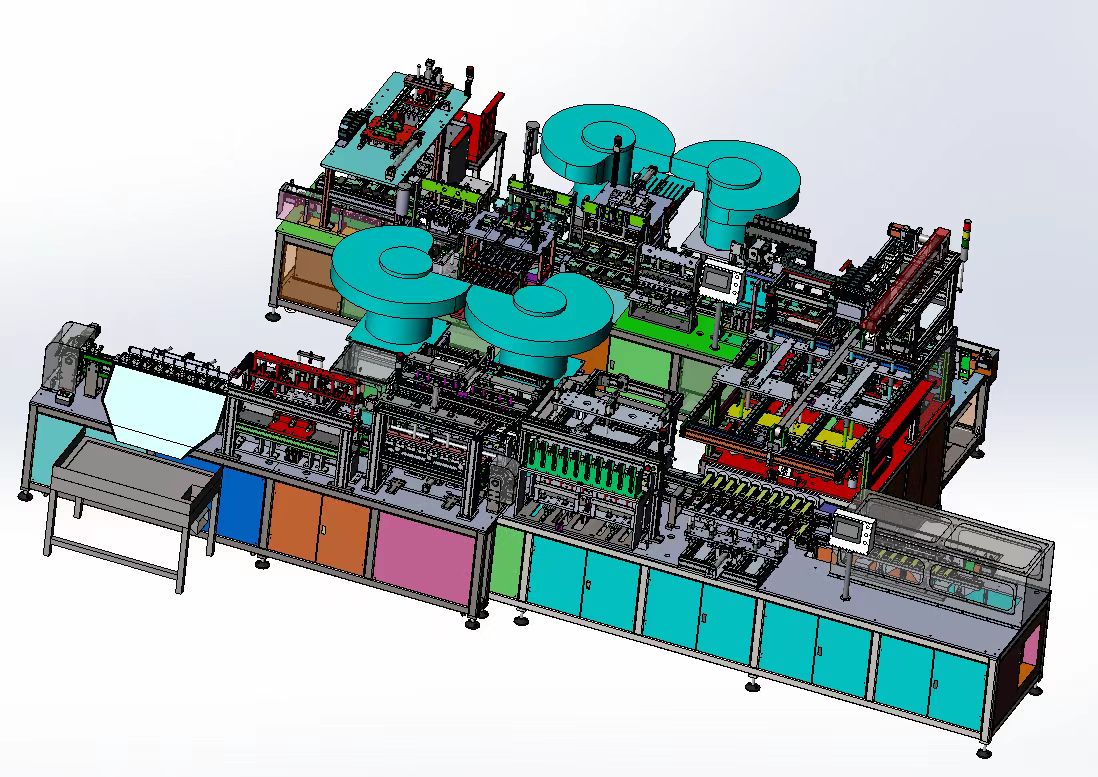

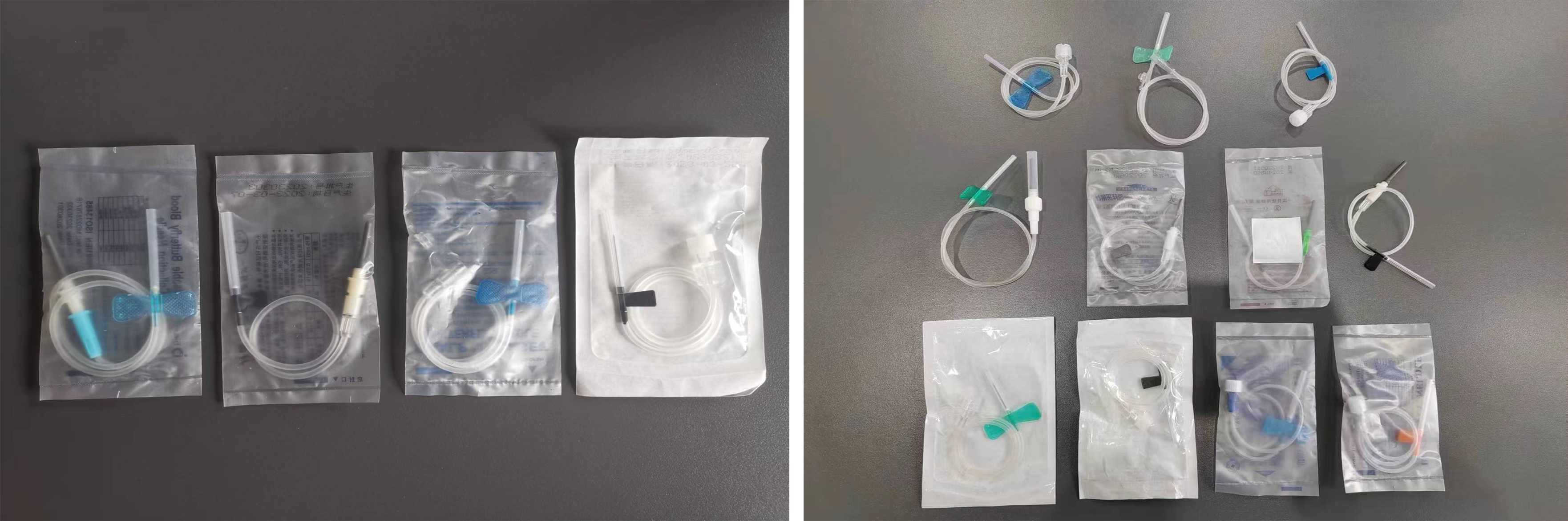

The main function of butterfly needle assembly and packaging machine is to assemble the four components of the venipuncture set, including the scalp vein needle, flexible tube, soft/hard needle seat, needle seat cap, then seal the assembled finished products into bags in a single automated process.

All of our fully automatic equipment are configured with Mitsubishi programmable logic controller&Japanese SMC pneumatic components, ensuring precise,reliable,efficient assembly and greatly avoid the potential for human error.

Parameters

| Power | Voltage | Air pressure | Capacity | Equipment size | Weight | Floor area | Pass rate | Operators required | One- time quantity of production |

|---|---|---|---|---|---|---|---|---|---|

| 15KW | 380 V, 50 Hz | Clean compressed air0.4 – 0.6 Mpa | 4000-4500pcs/h | 7*5.5m | 7-8 tons | 38.5m² | Assembly pass rate≥99.7% | 2 persons | 10pcs |

Configuration

| Pneumatic components | PLC System | Photoelectric Sensors | CCD Detection | Touch Screen | Servo Moto |

|---|---|---|---|---|---|

| SMC | Mitsubishi | Keyence/Panasonic | Keyence/Cognex | WEINVIEW | Taiwan Delta |

key innovations