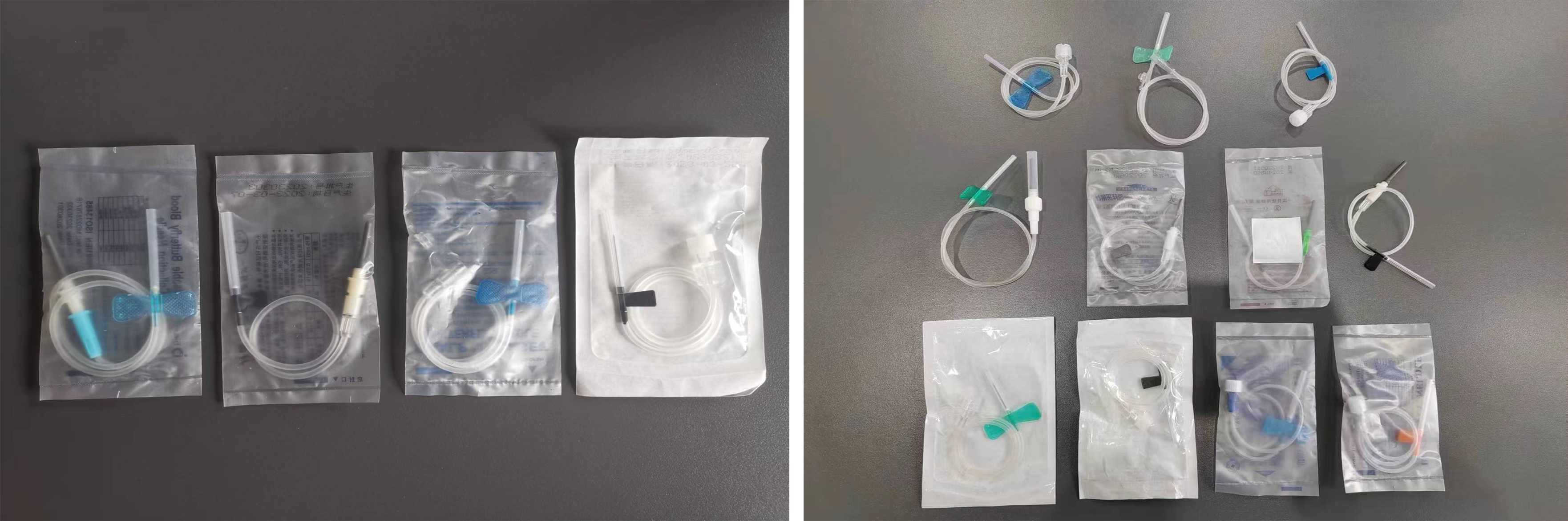

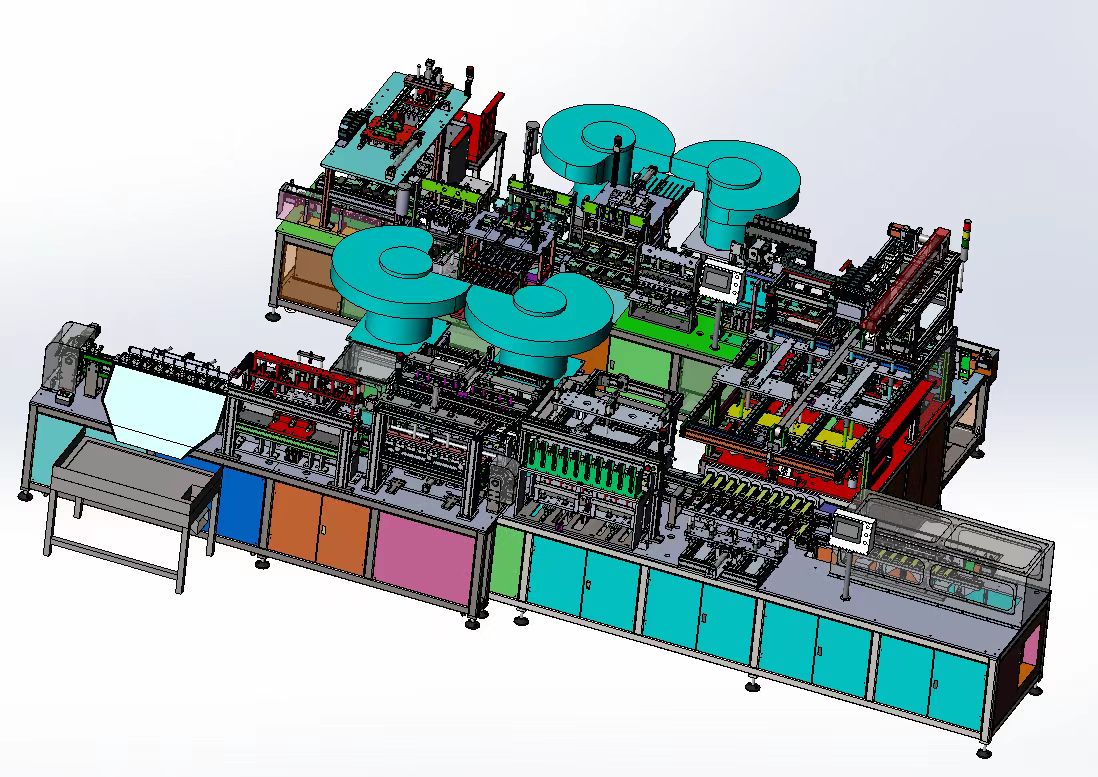

The main function of butterfly needle assembly and packaging machine is to assemble the four components of the venipuncture set, including the scalp vein needle, flexible tube, soft/hard needle seat, needle seat cap, then seal the assembled finished products into bags in a single automated process.

All of our fully automatic equipment are configured with Mitsubishi programmable logic controller&Japanese SMC pneumatic components, ensuring precise,reliable,efficient assembly and greatly avoid the potential for human error.

Parameters

| Power | Voltage | Air pressure | Capacity | Equipment size | Weight | Floor area | Pass rate | Operators required | One- time quantity of production |

|---|---|---|---|---|---|---|---|---|---|

| 15KW | 380 V, 50 Hz | Clean compressed air0.4 – 0.6 Mpa | 4000-4500pcs/h | 7*5.5m | 7-8 tons | 38.5m² | Assembly pass rate≥99.7% | 2 persons | 10pcs |

Configuration

| Pneumatic components | PLC System | Photoelectric Sensors | CCD Detection | Touch Screen | Servo Moto |

|---|---|---|---|---|---|

| SMC | Mitsubishi | Keyence/Panasonic | Keyence/Cognex | WEINVIEW | Taiwan Delta |

key innovations

Frequently Asked Questions

With so many years of experience in medical automation machines, we know that the following are questions that customers often ask, you can check the answers below. If you have any other questions, please feel free to contact us and we will respond to you quickly.