Types of IV infusion sets

IV infusion sets play a crucial role in intravenous therapy, IV infusion sets, come in various types design for specific therapeutic needs. Understanding these distinctions is extremely important for healthcare professionals and manufacturers alike.

Air vented IV infusion set, suitable to hard plastic drip chamber, incorporate a small air vent that can be opened or closed. This feature allows air to enter and displace fluid as it leaves the container, ensuring a smooth flow.

Non-vented IV infusion sets, conversely, without air vents in the spike. Suitable to flexible plastic drip chamber.

Filtered IV infusion set, it can filter contaminants in medications to enhance infusion safety for patients.

The ways to assemble IV infusion set

Normally, the infusion sets are consist of many components:plastic spike, air vent, air vent filter, spike cap,drip chamber,solution filter, drip tube,flow regulator body(roller clamp), flow regulator(roller), latex rubber injection site,precision filter,luer connector,needle,needle cover.It is a complicated structure.

1. Assemble IV infusion set by hands

About 20 years ago, automation technology has not been widely used in manufacturing industry. The workers assemble IV infusion sets by hands in the manufacturing facilities. Because there are so many assemble processes and procedures, the production capacities are very low at that time. Besides this, they are facing another problems caused by assembling manually, such as, low qualified products rate, product precision, lack of components, contaminants, etc.

2. Assemble IV infusion set by semi-automatic machines

After that, some automation technology companies have designed and developed automatic assembly machines for IV infusion set components, such as drip chamber assembly machine, clamp and roller assembly machine, luer connector and latex rubber injection site assembly machine, Y injection site assembly machine,precision filter assembly machine, etc. The machines are capable of assembling the mentioned components, the workers just need assemble all finished components together manually, We call this as a semi-automatically way to assembly IV infusion set. These improvements in automation technology helped them benefit a lot compared with all assemble processes by hands.

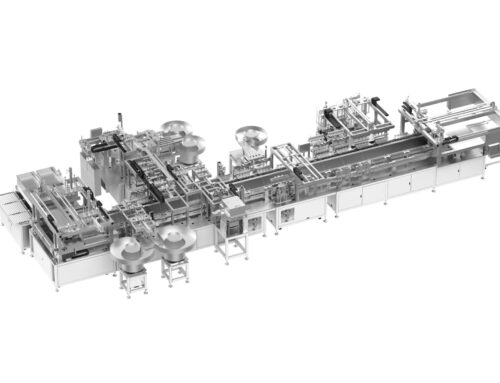

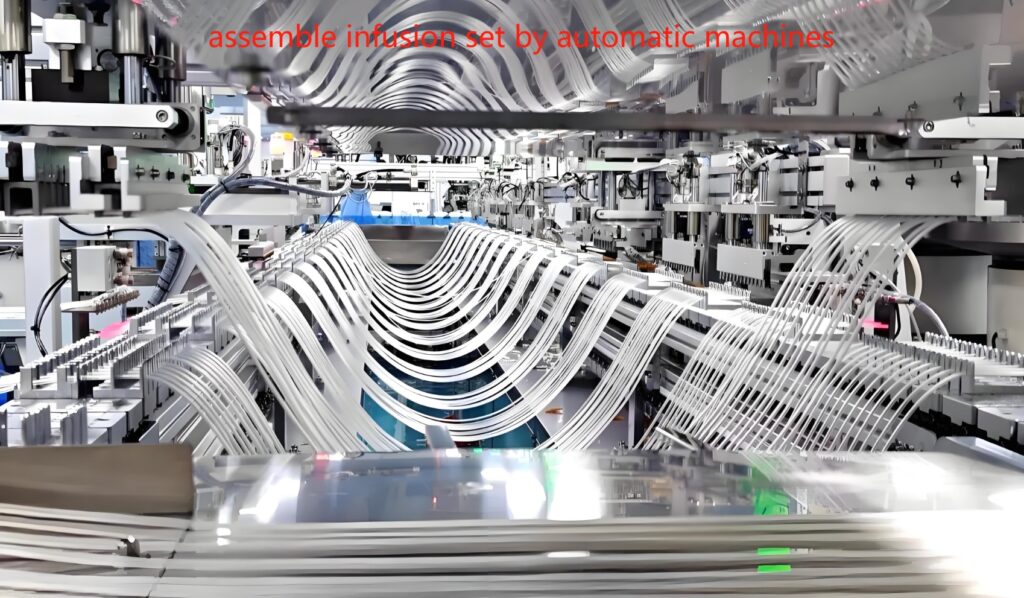

3. Assemble IV infusion set by full automatic machines

About 5 years ago, there are some IV infusion set manufacturers want to improve the production capacities and product quality to meet their customer’s requirements, Then the full automatically assembly machines were launched in that time.The operators put different kinds of materials and parts into “vibrating tray feeder” of every work position, then materials and parts will be arranged at the right position and be assembled accurately by PLC system.The mainly production processes are load the tube,load the roller clamp, load the roller, load the drip chamber,load the latex tube,load the luer connector, leakage inspection,load the needle,automatically reject defective infusion sets, unload qualified infusion sets.

The advantages of assembling IV infusion set by automatic assembly machine

-

Improve output and production efficiency;

-

Improves product quality,precision and reliability,;

-

Reduce labor cost for the factory owner.

-

Reduce the product cost.

Are you ready to update your manufacturing facilities? Or do you have a plan to build a new IV infusion set factory? Welcome to contact us to get a free quote now!